In mountain tunnel construction, spring water from the face and construction water generated during tunnel excavation is used to add fine-grained soil and concrete by drilling, dumping, and transporting waste, cement by chemical injection, injection materials, and various other materials. Water is often discharged as turbid water due to contamination with oil and other substances leaking from machinery used for underground work. The amount and quality of this turbid water vary depending on the scale, length, excavation method, geology, amount of underground spring water, etc. of the tunnel. Since tunnel construction requires a relatively long construction period, directly discharging turbid water into rivers, lakes, agricultural waterways, etc. will cause water pollution and damage the living and natural environments.

Generally speaking, SS (suspended solids), pH (hydrogen ion concentration), and oil content are problems in terms of environmental conservation in turbid water from tunnel construction. Depending on the construction, the regulatory values for treated water may include biochemical oxygen demand (BOD), chemical oxygen demand (COD), chromium content, etc. Also, spring water containing heavy metals can be a problem. When excavating in areas where industrial wastewater has flowed into the ground or in areas that contain heavy metals, separate measures must be taken.

When planning wastewater treatment, it is necessary to set the expected amount of wastewater and understand the wastewater standards.

Turbid raw water in tunnel construction can be divided into two types: underground spring water and construction water. Of these, there is often a large difference between the predicted and actual amount of underground spring water, and it can be said that it is difficult to accurately predict the amount of raw water at the planning stage. For this reason, a method has been adopted in which a minimum amount of turbid water treatment equipment is installed at the beginning of tunnel excavation, and equipment is added as the amount of spring water increases as the excavation progresses. In addition, when the amount of spring water increases, if there is no problem with the components of the spring water itself, the so-called clear turbidity separation method is used, which separates clear water and turbid water, and directly discharges clear water that does not contain fine soil or cement into a separate system. is often adopted.

Before construction begins, it is necessary to investigate the source of polluted water, its impact, its extent, related laws and regulations, regulatory values, etc., and carry out appropriate purification treatment before draining the water. In addition, the amount and quality of wastewater must be measured and reported in accordance with regulations and other regulations.

In general, we will discuss the points to keep in mind and countermeasures for treating SS, pH, and oil, which are problematic sources of water pollution.

[SS (suspended solid)]

The particle size composition of soil particles contained in drainage water during tunnel construction varies depending on the type of rock, its properties, shearing method, drainage method, etc. In many cases, a high proportion of particles are present. The sedimentation speed of these particles is very low and it takes a long time for them to settle. Therefore, physical and chemical treatments are applied to aggregate the particles and form fluffy floating particles (large particles produced by agglomeration). A method of accelerating sedimentation by forming aggregates of Flocculants used for floc formation include inorganic flocculants and polymer flocculants. PAC (polyaluminum chloride) is an inorganic flocculant mainly used for treating turbid water in tunnel equipment. Polymer condensing agents are sold by many manufacturers under their own brand names, and there are many types of products, but anionic ones are often used. These inorganic flocculants and polymer flocculants are often used together in anticipation of a synergistic effect.

[pH (Potential of Hydrogen)]

The pH of spring water generated during tunnel construction is generally around 6.5 to 7.5, but due to the contamination of shotcrete and chemical injection agents, the pH has increased to 9 to 13. It often becomes. Also, depending on the rock and soil quality of the ground, the spring water itself may be highly acidic or alkaline. When discharging wastewater into public water bodies, the pH must be adjusted to within the wastewater standard values. pH adjustment can be carried out either before or after sedimentation separation, and the former has been widely adopted recently because flocculation treatment can be carried out within the optimum pH range. Since many substances that inhibit this are mixed in, the amount of neutralizing agent used is somewhat larger than in post-neutralization. Carbon dioxide gas is generally used for alkaline wastewater, but dilute sulfuric acid may be used temporarily if the pH value is particularly high. For acidic wastewater, slaked lime or caustic soda is used.

[Oil content (normal hexane extract)] When

oils and fats leaking from tunnel excavation machines (rock drills, rock excavators, locomotives, rails, shear trucks) etc. mix into spring water, the concentration increases to 10 to 15 ppm. It may happen.

Oil is a problem mainly due to the generation of off-flavors and the odor it imparts to seafood, and even at low concentrations, it is necessary to consider removing it as much as possible. If oil is mixed into the raw water, a polyethylene cloth adsorbent is used in the raw water tank. (Reference material: “Mountain tunnel construction method from investigation and design to construction”, Geotechnical Society of Japan)

Environmental assessment

(environmental impact assessment)

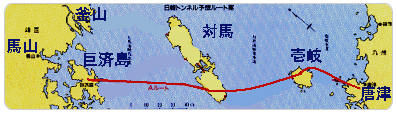

Overview of the Japan-Korea tunnel