If there is a risk that groundwater may be affected by construction, a thorough investigation must be conducted and appropriate measures must be taken as necessary.

When groundwater level lowering methods, pressure air methods, chemical injection methods, etc. are used together, or when mud is lost from a mud shield near a well, etc., or when backfilling is injected, the groundwater may be affected. Therefore, before construction begins, it is necessary to investigate the surrounding groundwater usage status and take appropriate measures to prevent possible impacts.

① Investigate the water level, water quality, flow direction, etc. of the surrounding ground and groundwater, and understand the overall trends (see Article 8).

② Investigate the existence of nearby wells, ponds, and reservoirs and their usage status. In particular, carefully investigate wells that provide water for domestic and business purposes.

③ When performing chemical injection, conduct an investigation based on the investigation items of the former Ministry of Construction's "Interim Guidelines for Construction Work Using Chemical Injection Method" (1974).

① Adoption of auxiliary construction methods Use

appropriate auxiliary construction methods such as pressurized air construction, chemical injection construction, freezing construction, and impermeable walls to prevent water from falling in the surrounding groundwater level.

In this case, in addition to the soil conditions, the appropriate auxiliary construction method should be selected by taking into account environmental conditions such as the soil overburden, overall ground composition, and surrounding wells.

② Preventing groundwater contamination by chemical injection

Chemical injection must be carried out while monitoring the water pollution situation by setting up side points in the surrounding area. For more information, refer to the former Ministry of Construction's "Interim Guidelines for Construction Work Using the Chemical Injection Method" (1974).

When work is carried out using the pressurized air method, a survey must be conducted in advance and appropriate measures must be taken to prevent the leakage of oxygen-deficient air, etc. from affecting the surrounding area.

When work is carried out using the pressurized air method, oxygen-deficient air or harmful gases may leak into nearby wells, basements, or other underground construction sites depending on ground conditions, so appropriate investigation and countermeasures must be taken in accordance with relevant laws and regulations. must be taken. Furthermore, if the stratum contains harmful gases such as methane and hydrogen sulfide, the risk factors will increase, so separate measures will need to be taken.

① "Ordinance on Prevention of Oxygen Deficiency Diseases, etc.: Article 24 (Measures Related to Pressurized Air Construction Methods)" stipulates investigations, measurements, preventive measures, etc. when performing work using pressurized air construction methods in oxygen-deficient locations.

② "Industrial Safety and Health Act Enforcement Order: Article 6, Paragraph 21" stipulates the appointment of a work chief and obliges work environment measurements for work in oxygen-deficient hazardous areas. Additionally, Annex 6 of the Enforcement Order specifies oxygen-deficient hazardous areas.

① Preliminary investigation and consideration

If the soil and groundwater investigation (see Article 8) indicates that there is a risk of leakage of oxygen-deficient air, etc., take measures to prevent accidents, such as investigating obstructing objects within the affected area (see Article 7). investigation and consideration must be conducted.

②Preventive Measures

Measure the oxygen concentration in the air in wells, basements, and other places where there is a risk of leakage within a 1km radius and ensure monitoring.

In addition, if it is necessary to avoid the effects of exposure, take appropriate preventive measures and safety measures. (Reference material: "Tunnel Standard Specifications - Shield Construction Method Established in 2006", Japan Society of Civil Engineers)

Environmental assessment

(environmental impact assessment)

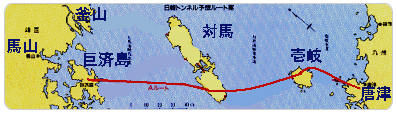

Overview of the Japan-Korea tunnel