*Seikan Tunnel

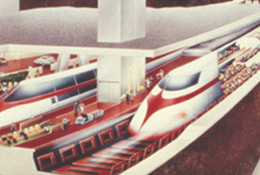

Since this tunnel is positioned as part of an international highway project, the most desirable driving method is for cars to be able to drive on their own. Therefore, it is necessary to consider this first. Many tunnels for automobiles have been built in Japan to date, and the standard for their size has now been established, as shown in Figure 1.

If the transportation demand is less than 10,000 vehicles/day, there will be one lane in each direction, and this single tunnel will be used for both the up and down lines. When transportation demand increases, another tunnel similar to this one will be added and used as a two-lane tunnel in each direction. Also, since it is an undersea tunnel, it is necessary to provide an advanced guide shaft and a working shaft. Looking at the example of the Seikan Tunnel, it seems likely that each tunnel will be constructed in the layout shown in Figure 2. The advanced shaft and working shaft will be used for ventilation and pipelines even after the tunnel is opened, and will also be used for maintenance work. Regarding the Japan-Korea tunnel, in response to future communication and energy issues, joint management of various facilities such as optical communication cables, superconducting power transmission facilities, natural gas supply facilities, and drinking water transportation due to future global warming is being considered. It will be done.

*Honshu-Shikoku Connecting Bridge

However, the biggest problem in this case is ventilation. Cars emit exhaust gas, so long tunnels require large ventilation equipment. Figure 3 shows the ventilation equipment at the Kanetsu Tunnel, which was built by the Japan Highway Public Corporation , and the equipment is quite extensive (for reference, the Eurotunnel and the Tokyo Bay Crossing Road is shown).

This ventilation system uses vertical shaft ventilation, and the construction cost is slightly lower than that of the cross-flow system.

However, in the case of the Japan-Korea tunnel, it would be several dozen times as long as the above-mentioned tunnels, so the cost for ventilation equipment would be extremely high. An even more decisive disadvantage is that since it is an undersea tunnel, vertical shafts and inclined shafts cannot be built. The total ventilation rate varies depending on the traffic volume, but a rate of 1,000 to 2,000 m3/s is required, and in land tunnels, the tunnels are divided into sections every 1 to 2 km, and vertical shafts are installed to transport air from the ground. If we calculate the total length to be 20 times that of the Kanetsu Tunnel and the blower horsepower per unit length to be three times, we can see that the electricity costs alone would amount to more than 10 billion yen per year, making it an unrealistic plan.

All methods of self-driving cars through tunnels have various difficulties. However, it is likely that this tunnel will not open in 20 to 30 years, so it is likely that a new Intelligent Transport System (ITS) will be developed in the meantime to enable autonomous driving inside the tunnel. In addition, quite practical uses are conceivable, such as the practical application of current collector electric vehicles. Incidentally, the inside of a tunnel is a closed space, and it is difficult to manually drive there for a long time due to psychological pressure and the like.

All methods of self-driving cars through tunnels have various difficulties. However, it is likely that this tunnel will not open in 20 to 30 years, so it is likely that a new Intelligent Transport System (ITS) will be developed in the meantime to enable autonomous driving inside the tunnel. In addition, quite practical uses are conceivable, such as the practical application of current collector electric vehicles. Incidentally, the inside of a tunnel is a closed space, and it is difficult to manually drive there for a long time due to psychological pressure and the like.

Therefore, although it is necessary to automate driving in tunnels, there is no need for completely unmanned driving; there are people actually riding in the car, so automatic driving equipment should be able to coordinate with human movements. In addition, it may be of the nature of assisting a person's driving operation.

Therefore, although it is necessary to automate driving in tunnels, there is no need for completely unmanned driving; there are people actually riding in the car, so automatic driving equipment should be able to coordinate with human movements. In addition, it may be of the nature of assisting a person's driving operation.

For this reason, it will be necessary to design tunnels that take into account ergonomic considerations, such as the use of an AHS system (AHS) and the arrangement of lighting and traffic lights.

Therefore, the simple induction type of current collector type cars mentioned earlier will be one of the aids to automatic driving. In addition, it will be necessary to introduce signal safety equipment for the guideway to prevent collisions in the longitudinal direction. Another problem is that in Japan you drive on the left, but in Korea you drive on the right. When driving a car through the Japan-Korea Tunnel, you must drive on the left until Tsushima, according to domestic regulations. Therefore, it is necessary to make a left/right switch somewhere between Tsushima and Geoje Island. If customs clearance procedures are carried out at some point, that point will become a turning point. At this point, all vehicles stop and passengers exit, making it easier to turn left and right. However, if borders become almost free to cross, as is currently the case in European countries, it will be necessary to create a left-right turning point using a grade crossing somewhere. In this case, it is necessary to make sure that the driver fully understands that the left and right sides have been swapped, and to take every possible precaution to prevent accidents.

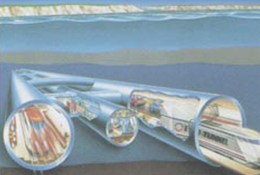

There are many achievements in the past in passing railways through long tunnels. Currently, the world's longest Seikan tunnel has a total length of 53.85km. The total length of the Japan-Korea tunnel is 250km, and it connects the islands of Iki and Tsushima. In this case, due to the linear relationship between Iki and Tsushima, it would be impossible to reach the surface and it would be an underground tunnel. However, this tunnel is the same as an underground tunnel on land, so the longest distance under water is about 70km from Tsushima to Geoje Island. Therefore, if we extrapolate the experience of the Seikan Tunnel and apply it to a railway tunnel, there will be few technical problems. Figure 4 shows a cross section of the Seikan Tunnel , which was constructed based on Shinkansen standards.

It would be preferable for the Japan-Korea tunnel to be constructed to roughly the same standards. In addition, if the tunnel is excavated by a machine such as a boring machine (TBM), the tunnel cross section will be circular, as shown in Figure 5. However, as will be explained later (at the time of the research, there was no intention to introduce French-made TGVs, and future research will be compared with this TGV ), the vehicle limit for direct trains within Korea is slightly smaller than Japan's Shinkansen. Therefore, the cross section of the tunnel can also be made slightly smaller. There is a possibility that Japan's Shinkansen will be used to reach Busan, and the vehicle capacity of Korean National Railways above the platform is almost the same as that of Japan's Shinkansen.

Therefore, it is thought that the above-mentioned cross section will be used as the tunnel cross section.

Therefore, it is thought that the above-mentioned cross section will be used as the tunnel cross section.

Naturally, the tunnel section will be an electric track, so as shown in this cross-sectional diagram, it will be necessary to run an overhead contact line and supply power to it. Since the vehicle running is a Shinkansen train, the electric system is 25KV AC. Therefore, substations with a capacity of about 30,000 KVA must be installed every 20 to 30 km. Furthermore, depending on the progress of the Yamanashi Maglev Line (see: future Japan-Korea tunnel concept diagram), which is currently in the experimental stage, it is expected that it will have a significant impact on the intelligent transportation network system between Japan and South Korea, and even throughout Northeast Asia. I can say that.

Regarding linear motor cars, at the 8th meeting (2000) of the ``Superconducting Magnetic Levitation Railway Practical Technology Evaluation Committee'' consisting mainly of academic experts, ``Long-term durability and economic efficiency Although there are still issues that the department will continue to consider, it is considered that the technical prospects for practical application as an ultra-high-speed mass transit system are well established."

In order to resolve issues such as long-term durability, cost reduction, and improvement of the vehicle's aerodynamic characteristics, it was decided that running tests aimed at practical application would continue for approximately five years from 2000 onward in advance sections. (Reference site: Ministry of Land, Infrastructure, Transport and Tourism, "Maglev Motor Car" homepage) As the total length of the Seikan Tunnel is 54km, power is supplied from substations installed on both sides of the tunnel. In the case of the Japan-Korea tunnel, substations will be installed on land between Kyushu, Iki, and Tsushima to supply electricity to the tunnel. However, since the tunnel between Tsushima and Geoje Islands stretches for 70km, one or two substations must be installed in between. Therefore, it is necessary to secure a space of approximately 20m x 15m x 30m on the seabed and run high-voltage cables to that point. Furthermore, if the railway is used, there is no need to install a terminal because passengers will be able to travel through the railway (However, due to the introduction of French-made TGVs, there will be differences in signal and control systems, and interoperability will be an issue for future consideration).

Regarding freight transportation, if the Shinkansen is connected to the Korean railway through the Japan-Korea Tunnel, the Shinkansen track and the railway track in Korea (including TGV) are both standard gauge (1435 mm), so the Japan-Korea Tunnel will be used. Freight trains passing through it can go directly to anywhere in South Korea.

Regarding freight transportation, if the Shinkansen is connected to the Korean railway through the Japan-Korea Tunnel, the Shinkansen track and the railway track in Korea (including TGV) are both standard gauge (1435 mm), so the Japan-Korea Tunnel will be used. Freight trains passing through it can go directly to anywhere in South Korea.

However, Japan's Shinkansen trains are built as passenger-only railways, so they have some problems, such as difficulty in transporting general cargo. Conversely, the track standard for Japan's conventional lines is narrow gauge (1066 mm), making direct service impossible. Therefore, since container transport will be the mainstay, a container transshipment base will be located on the Kyushu side.

This would require a fairly large transshipment terminal, but one idea would be to use surplus railway freight equipment from the Chikuho coalfields. Here, the containers loaded on the Japanese freight cars are transferred to the freight cars that go directly to the Korean side. Although there are few examples of transshipment of containers between railway freight cars in the world, the example of this being done for international cargo at the border between Spain and France is a good example. The base also handles the transshipment of containers destined for South Korea transported by truck from northern Kyushu and the western Chugoku region onto container wagons, and vice versa. Looking only from the perspective of freight transportation, the situation would be similar to that of South Korean railways being extended to a base in northern Kyushu. It is not appropriate to transport large bulk cargoes (coal, cement, ore, grain, etc.) by rail through the Japan-Korea tunnel. Given that large cargo is being transported domestically by coastal shipping, the same concept will apply to transport between Japan and South Korea.

Railways can generally transport cars by loading them onto freight cars.

Railways can generally transport cars by loading them onto freight cars.

Therefore, it is possible to load and transport a car on the railway only in the tunnel section, and once it exits the tunnel, it can drive itself and reach its destination. In the case of trains (Le Shuttle) operating in the Channel Railway (Euro) Tunnel two-tier (sometimes one-tier = large car) freight cars, and passengers are generally seated in passenger cars. A car train system is used, where you ride directly.

Loading and unloading of passenger cars onto freight cars is carried out by staff on their own.

In general, something called car sleeper is popular in Europe. In this case, passengers sleep in the sleeping car, arrive near their destination the next morning, and drive from there on their own. The same method is applied to tunnel passage. Of course, since the railway operates directly, it can be used not only in tunnels, but also in longer distance sections, such as using sleeping cars.

Freight vehicles can also be transported by rail only within tunnels in a similar manner.

However, if a large freight vehicle is placed on a regular freight car, it may exceed the vehicle capacity, so methods such as using the freight car as the bottom floor or lowering only the wheels, such as kangaroos, are used. In this way, when loading a car onto a freight car, a space is needed to park the car for a meeting. This can also be called a ferry terminal. The space for this will vary depending on the amount of transportation, but it will require the space for 200 to 300 passenger cars and an area of 10,000 to 15,000 m2. Facilities for resting passengers and truck crews will also be required. This is similar to an expressway service area.

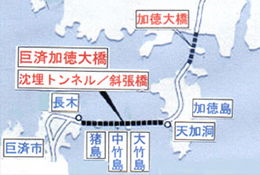

The South Korean government plans to construct an expressway connecting Busan and Geoje Island (total length, 8.2 km), with completion scheduled for 2009. The project consists of two oblique bridges with a total length of 230 m and 475 m, and a 3.4 km immersed tunnel 40 m deep.

The groundbreaking ceremony for the connecting road (Geoga Bridge) connecting Gadeok Island in Busan City and Geoje Island in South Gyeongsang Province (Gyeongsangnam Province) was held on November 27, 2003 in front of the Busan New Port Public Relations Center.

The groundbreaking ceremony for the connecting road (Geoga Bridge) connecting Gadeok Island in Busan City and Geoje Island in South Gyeongsang Province (Gyeongsangnam Province) was held on November 27, 2003 in front of the Busan New Port Public Relations Center.

Until 2010, project costs amounted to 1,446.9 billion won (approximately 144.7 billion yen).

This road is 8.2 km long and has 4 up and down lanes, connecting Cheonga-dong, Gadeok-do, Gangseo-gu, Busan, and Yuho-ri, Jangmuk-myeon, Geoje, Gyeongsangnam.

Of the entire section, the 3.7km section between Katokushima and Otakeshima is the first in Japan to use the immersed tunnel construction method, in which a structure is built on land and fixed to the seabed. The 4.5km section will be constructed as two cable-stayed bridges.

The construction of the project will be carried out by GK Marine Road, a consortium of eight domestic companies, including Daewoo Construction, Daelim Industrial, and Doosan Construction, with an investment of 999.6 billion won, while the government, Busan City, and Gyeongsangnam-do will spend 447.3 billion won. support.

Upon completion, this road will belong to Busan City and Gyeongsangnam-do, but for 40 years a ``BOT'' system has been introduced in which the builder collects tolls and manages and operates the road. Once this road opens, the distance between Busan and Geoje will be shortened from 140km to 60km, and travel time will be shortened from 2 hours and 10 minutes to 50 minutes. It will also help disperse traffic on the Namhae Expressway and Gyeongbu Expressway, and will greatly help in processing import and export goods for Busan/Shinko Bay, Mengsan/Shinho Industrial Complex, Geoje/shipbuilding industry. Prior to this, in October 2003, Busan City held a groundbreaking ceremony for the construction of ``Gadeok Bridge'', which is part of the ``Busan-Geoje'' connecting road, and construction began.